Product Overview

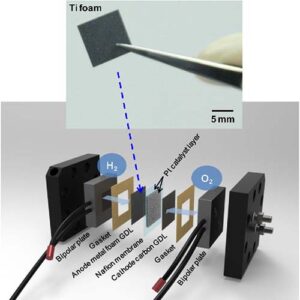

Titanium Fiber Felt is a three-dimensional porous metal material made from TA1 pure titanium fibers. It is produced using precise fiber-laying technology and high-temperature vacuum sintering according to international standards. This material is specifically designed for use as the anode gas diffusion layer (GDL) in PEM (Proton Exchange Membrane) water electrolysis hydrogen production systems. Its advantages includes excellent corrosion resistance (ability to withstand the strong acidic environment of the anode), moderate conductivity and good mechanical strength, which can effectively support the fragile membrane electrode structure.

Key Characteristics:

- Uniform pore structure and high porosity (50–90%)

- Excellent corrosion resistance in acidic electrolytes

- High electrical conductivity and low contact resistance

- Superior water permeability and thermal conductivity

- Capable of supporting high current density with low voltage

- High mechanical stability and long service life

In PEM electrolyzers, the titanium fiber felt is positioned between the anode catalyst layer and the flow field plate, performing three critical functions:

- Conductivity: Provides a highly conductive pathway to reduce contact resistance and enhance system efficiency

- Gas/Liquid Diffusion: Ensures efficient oxygen release and uniform electrolyte distribution to prevent flooding

- Mechanical Support & Corrosion Protection: Maintains structural integrity under high pressure and acidic environments and protects the catalyst layer from damage

This is why titanium fiber felt is considered an irreplaceable core material in PEM water electrolysis technology.

Key Features for Hydrogen Electrolyzers

| Feature | Function in Water Electrolysis |

| High Electrical Conductivity | Reduces contact resistance and improves efficiency |

| High Porosity (50–90%) | Enables rapid gas release and prevents bubble blockage |

| Excellent Corrosion Resistance | Stable in acidic electrolytes (H₂SO₄, H₃PO₄) for over 10,000 hours |

| High Mechanical Strength & Resilience | Supports MEA (Membrane Electrode Assembly) without deformation |

| Customizable Design | Thickness, pore size and surface density adjustable for systems from 1 to 1000 Nm³/h |

Technical Specifications

| Parameter | Value/Range |

| Material | TA1 Pure Titanium Fiber |

| Thickness | 0.1 – 1.5 mm |

| Porosity | 50% – 90% |

| Surface Density | 175 – 2030 g/m² |

| Max Sheet Size | 1200 × 1200 mm (custom sizes available) |

| Operating Temperature | -200°C to 600°C |

| Permeability | ≥ 400 L/(min·dm²) |

Applications

✅ PEM Water Electrolysis Hydrogen Production

- Used as the anode gas diffusion layer (GDL)

- Bridges catalyst layer and flow field plate

- Enhances gas transport and catalytic efficiency

✅ Fuel Cells

- Functions as a diffusion medium/electrode support material

Tips for Identifying the Quality of Titanium Fiber Felt

To determine whether titanium fiber felt is of good quality or not, you can use the following methods:

① Check the surface appearance

- If the surface fibers are shorter than 60 mm, it is considered a low-quality product. This type of titanium fiber felt has a shorter lifespan, lower pressure resistance, and becomes loose more easily, causing the voltage to rise faster during use.

- A high-quality titanium fiber felt should have a smooth and even surface, without burrs, pimples, or wrinkles. The surface quality directly reflects the material quality of the titanium fibers and has a great impact on the service life of the membrane electrode.

② Water drop penetration test

- Drop a few drops of water onto the surface of the titanium fiber felt. If the water quickly penetrates through to the other side, it is a high-quality product. This indicates good permeability and air–water transfer capability.

- If the water remains on the surface and does not seep through, it is a low-quality product. Such poor-quality felt may cause insufficient water supply to the membrane electrode, leading to a rapid increase of voltage and heat generation, and a shortened lifespan of the membrane electrode.

③ Resistance test

- Install the titanium fiber felt samples into the same membrane electrode electrolyzer for comparison. If the operating voltage is higher, that sample is of lower quality.

- Low-quality titanium fiber felt results in lower current output and shorter service life, especially under higher current densities (e.g. 1.5 A/cm²), where the difference becomes more obvious.

Why Choose Our Titanium Fiber Felt?

- Manufactured to international standards, replacing brands like Bekaert and GKN Powder Metallurgy

- Widely used in Europe and the United States

- Proven for PEM hydrogen production, renewable energy systems, medical equipment, and research institutions

- Custom thickness, pore size, density, and surface treatments available