Product Overview

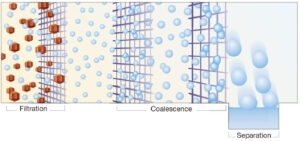

The Coalescence Filter Element is designed for gas-liquid and liquid-liquid separation, effectively removing fine liquid droplets or mist from gas or liquid streams. It works through a multi-stage process of capture, coalescence, and drainage, ensuring efficient impurity removal and clean output.

The gas-liquid coalescence filter captures and merges small liquid droplets suspended in gas, while the liquid-liquid coalescence filter separates immiscible liquids such as oil and water. Depending on the working condition, specialized metal or non-metal filter media can be selected to achieve optimal separation efficiency and durability.

FiltraMate Coalescence Filter Elements are direct replacements for your existing coalescer elements, with the benefits of fast delivery and competitive pricing. They are fully interchangeable with existing installations—no need to modify current filter housings. We offer alternatives for major brands such as Parker, 3M, Hydac, Dollinger, Filtration Group (formerly Mahle), Peco, Eaton, Donaldson Peerless, Pentair, GEA, and more.

Filter Material

• Coalescence Filter Element: Non-metal composite materials; metal options available for special service

• Separation Filter Element: Specially treated metal materials; customized materials available upon request

Key Features

• Continuous dynamic coalescence process ensures stable and efficient filtration

• Specially treated filter media for enhanced droplet merging and separation

• Configurable solutions for different operating environments and requirements

• High resistance to temperature, pressure, and chemical corrosion

Technical Specifications

Gas-Liquid Coalescence Filter:

• Filtration Efficiency: 99.999% for 0.3 μm

• Max Differential Pressure: 0.5 MPa

• Max Operating Temperature: 120°C

Liquid-Liquid Coalescence Filter:

• Filtration Precision: ≤30 ppm (depends on service conditions)

• Max Differential Pressure: 0.35 MPa

• Max Operating Temperature: 150°C

Applications

Gas-Liquid Coalescence Filter:

• Gas drying and mist separation after air compressors

• Amine and glycol extraction towers

• Removal of lube oil mist in fuel or chemical plants

• Gas-liquid separation in compressor seal systems for stable operation

Liquid-Liquid Coalescence Filter:

• Separation of water from fuels (gasoline, aviation fuel, diesel)

• Separation of oil from quenching water

• Separation of amines from liquefied petroleum gas (LPG)