Filter element clogging too fast is one of the most common complaints in industrial filtration systems.

However, not all filter element clogging means a filter problem.

To identify the real cause, it is critical to understand how filter elements are designed to work and how normal and abnormal clogging differ in real applications.

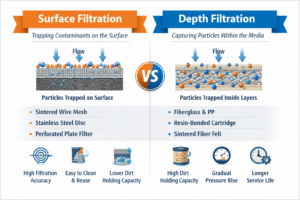

2.1 Surface Filtration – Trapping Contaminants on the Surface

Surface filtration works by blocking particles mainly on the outer surface of the filter media. The pores are uniform and precisely controlled, allowing only particles smaller than the pore size to pass through.

Typical characteristics:

• Uniform pore size

• High filtration accuracy

• Easy to clean and reusable

• Contaminants accumulate on the surface, forming a filter cake

Common filter element types using surface filtration:

• Sintered mesh filter elements

• Sintered metal filter discs

• Perforated plate composite sintered mesh filters

Typical applications:

• High-temperature gas filtration

• Polymer melt filtration

• Hydraulic oil filtration with controlled contamination levels

• Flame arresting and safety filtration systems

Limitation:

Surface filters usually have lower dirt-holding capacity than depth filters. When used in systems with high contamination load, they can clog rapidly if not properly sized or supported by pre-filtration.

2.2 Depth Filtration – Capturing Particles Layer by Layer

Depth filtration captures contaminants throughout the entire thickness of the filter media rather than only on the surface. The pore structure is usually gradient-based, with larger pores on the outside and finer pores toward the inside.

Typical characteristics:

• High dirt-holding capacity

• Gradual pressure increase

• Longer service life in dirty systems

• Excellent performance for fine and soft contaminants

Common filter element types using depth filtration:

• String Wound Filter Cartridge

• Polypropylene (PP) filter cartridges

• Resin-bonded (phenolic) filter cartridges

• Sintered metal fiber felt filter elements

• Coalescence filter elements

Typical applications:

• Hydraulic and lubrication systems

• Air compressor oil and separator filters

• Chemical and petrochemical processing

• High-viscosity fluids such as resins, coatings, and inks

Advantage:

Depth filtration is ideal when contaminants are fine, soft, or present in large quantities, as it delays clogging and stabilizes pressure drop.

2.3 Normal Clogging – Expected and Controlled Filter Behavior

Normal clogging is a natural and expected process where contaminants gradually accumulate until the filter reaches its designed dirt-holding capacity.

Typical signs of normal clogging:

• Pressure drop increases slowly and steadily

• Filter reaches expected service life

• No sudden flow restriction

• Filter media structure remains intact

Case example – Normal clogging:

In a hydraulic lubrication system using a fiberglass depth filter rated at 10 μm, the pressure drop rises gradually over 2,000 operating hours. The filter is replaced at the recommended differential pressure limit, with contaminants evenly distributed inside the media.

➡ This indicates correct filter selection and system design.

Normal clogging means the filtration system is working exactly as intended.

2.4 Abnormal Clogging – A Warning Sign of System Mismatch

Abnormal clogging occurs when a filter blocks much faster than its designed service life. This is usually a sign of incorrect filter selection or unexpected system conditions.

Typical signs of abnormal clogging:

• Rapid pressure spike shortly after installation

• Uneven contamination concentrated on the surface

• Filter collapse or deformation

• Frequent, costly replacements

Case example 1 – Precision too fine:

A 1 μm surface filter is installed directly in a system with heavy solid contamination. The filter element clogging occurs within hours instead of weeks.

➡ Root cause: filtration accuracy too fine, no pre-filtration stage.

Case example 2 – Wrong media for viscosity:

A standard PP filter cartridge is used in a high-viscosity resin filtration process. Resin gels block the pores quickly, causing sudden pressure rise.

➡ Root cause: incorrect media; resin-bonded or fiber felt filter should be used.

Case example 3 – Excessive flow rate:

A hydraulic system operates above the filter’s rated flow. The filter media compresses, pore size shrinks, and clogging accelerates.

➡ Root cause: flow rate exceeds design limits.

Understanding surface filtration, depth filtration, and clogging behavior helps engineers select the right filter element, avoid premature failure, and reduce operating costs.

In most cases, fast filter element clogging is not a quality issue, but a mismatch between filter design and system conditions