Product Overview

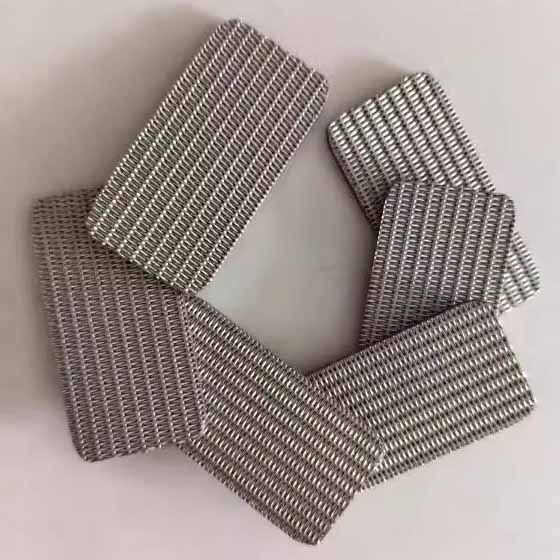

The sintered filter disc is made from multi-layer stainless steel sintered mesh, which are compressed and vacuum sintered at high temperatures. This process forms a rigid, corrosion-resistant, high-strength filter structure with uniform pore distribution.

Unlike ordinary woven mesh, sintered filter discs are structurally stable, pressure-resistant, and reusable, making them ideal for applications requiring fine filtration, flame blocking, or explosion protection. They are widely used in petrochemical, pharmaceutical, food processing, machinery, and gas filtration systems.

Key Features & Benefits

| Feature | Description |

| Multi-layer structure & high strength | Made from 5-6 layers of stainless steel mesh, sintered into a single rigid piece for excellent compressive and mechanical strength. |

| Stable filtration accuracy | Pore sizes range from 1 μm to 200 μm, ensuring consistent particle retention without deformation. |

| High temperature & corrosion resistance | Operates continuously from -200°C to 600°C in acids, alkalis, oils, and high-pressure gases. |

| Explosion-proof & flame blocking | Can stop flame propagation and gas backfire—suitable for fuel gas systems, chemical reactors, and safety valves. |

| Washable & reusable | Supports backflushing, ultrasonic cleaning, steam and chemical cleaning, offering a long service life. |

Technical Specifications

| Parameter | Value |

| Material | SS304, SS316, SS316L, Monel, other alloys on request |

| Diameter | 10 mm – 1000 mm |

| Thickness | 1 mm – 5 mm |

| Filtration Precision | 1 μm – 200 μm |

| Operating Temperature | -200°C to 600°C continuous |

| Structure Types | Split type & Integral type |

| Shape Options | Round, ring, square, oval, polygonal, custom |

Application Fields

| Industry | Typical Uses |

| Oil & Petrochemical | Oil-water separation, fuel filtration, flame blockers, explosion-proof systems |

| Chemical Processing | Catalyst recovery, reaction gas filtration, acid & alkaline purification |

| Pharmaceutical & Food | Gas sterilization, liquid clarification, drying, powder recovery |

| Gas & Energy Systems | Natural gas separators, LNG filtration, fireback prevention |

| Machinery & Equipment | Hydraulic filtration, compressor protection, high-pressure fluid systems |

| Explosion-proof & Safety Systems | Flame blocker cores, pressure vessel protection, storage tank vent safety |

Frequently Asked Questions (FAQs)

Q1. What is the maximum operating temperature?

A: Stainless steel sintered filter disc can handle 200°C–600°C, while some high-alloy versions can reach up to 800°C..

Q2. Can it be made other shaps other than Round?

A: Yes, we can make it rectangle, square, oval, polygonal, and other customized shapes.

Q3. Can it be cleaned and reused? How?

A: Yes. Cleaning methods include backwashing, ultrasonic cleaning, steam or solvent cleaning, restoring original permeability.

Q4. Can it be used for explosion or flame protection?

A: Absolutely. The porous metal structure absorbs heat, stops flames from spreading, and prevents flashback—commonly used in flame blockers.

Q5. Can I customize size and filtration accuracy?

A: Yes. We offer custom options for diameter, thickness, material, pore size, and pressure rating to match your equipment and application.